Services

All the services you need in one place.

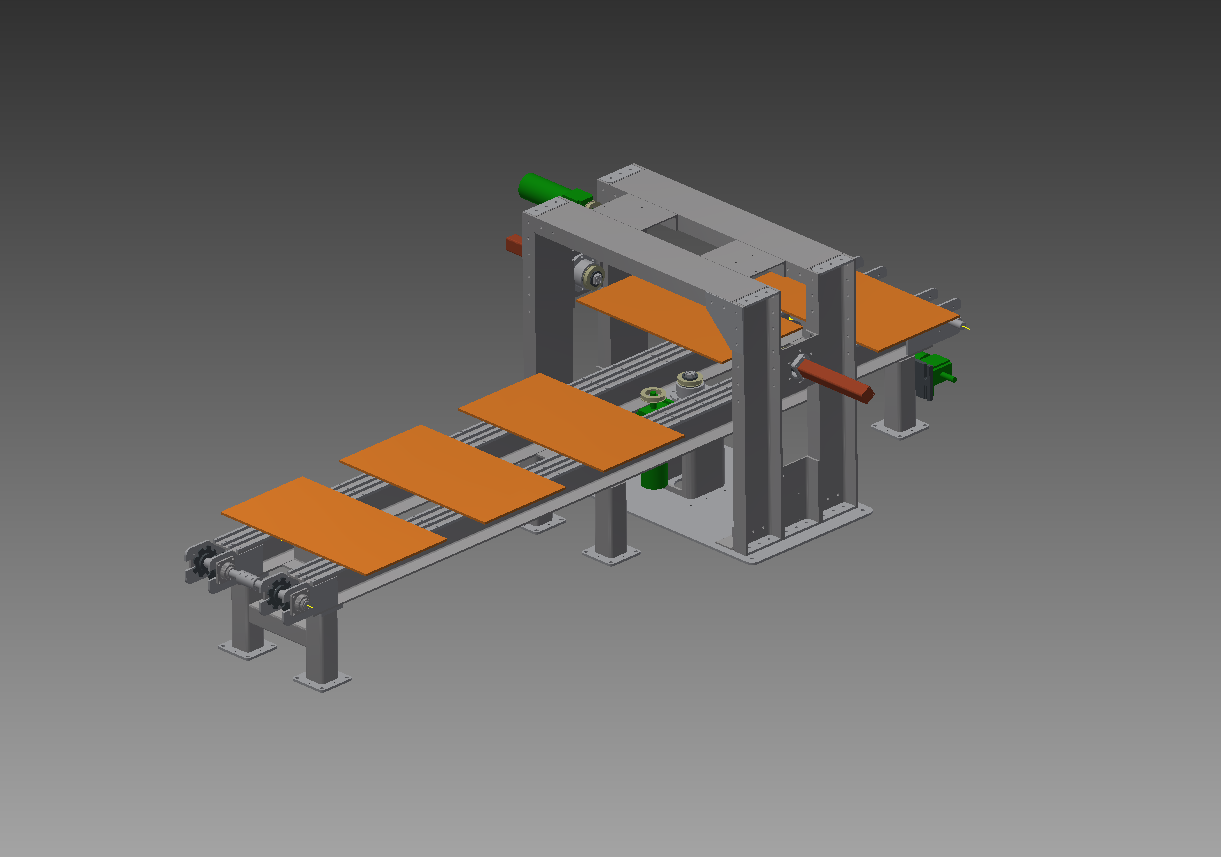

IJF Engineering consists of multiple parts. We have a design office that focuses on two main areas; component design and assembly design. Using 3D CAD modelling software, we are able to produce models of the various components and engineering drawings to be issued for manufacture. Our engineers are always happy to come to site to discuss and solve any issues you may be having no matter how large or small.

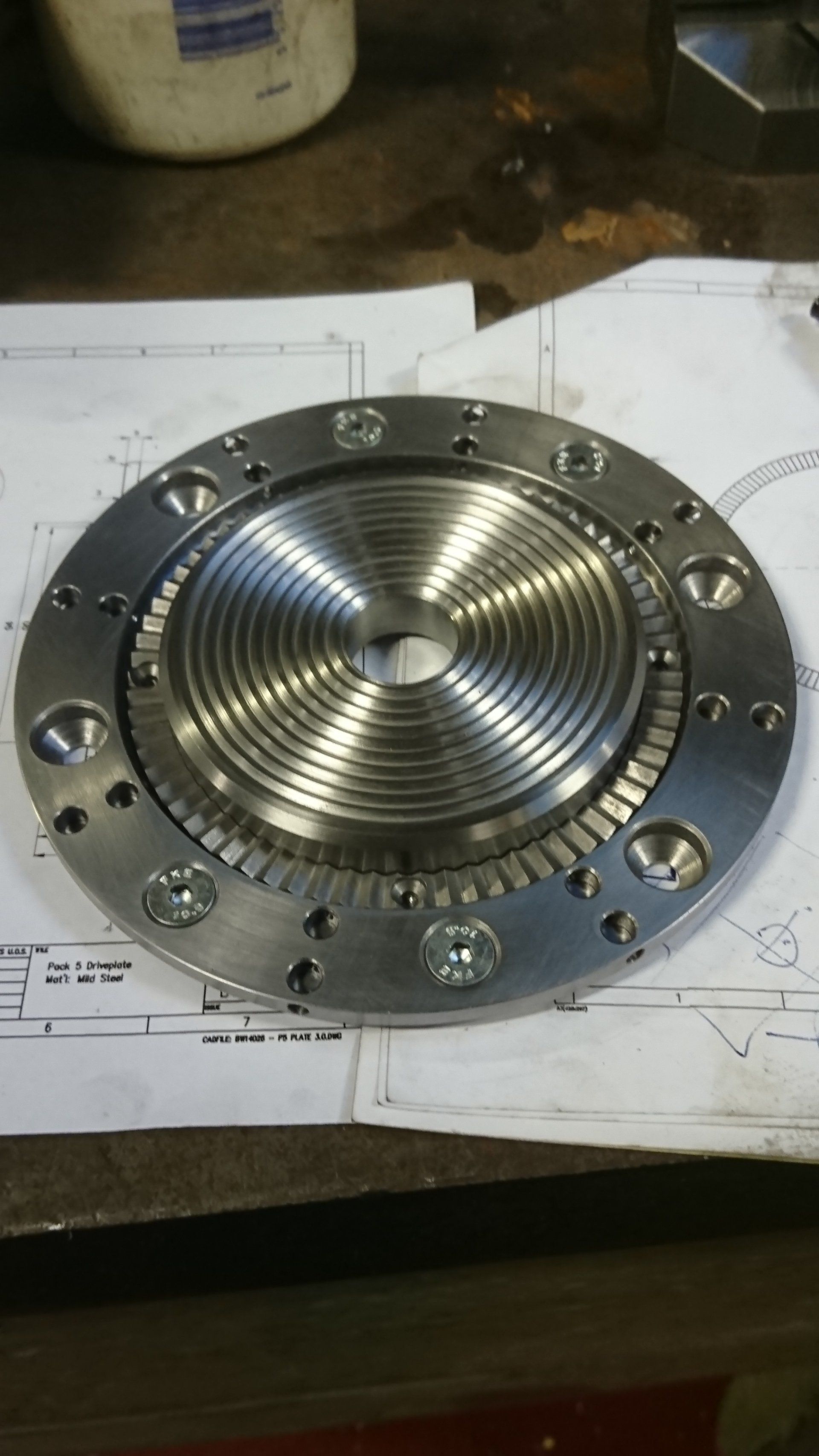

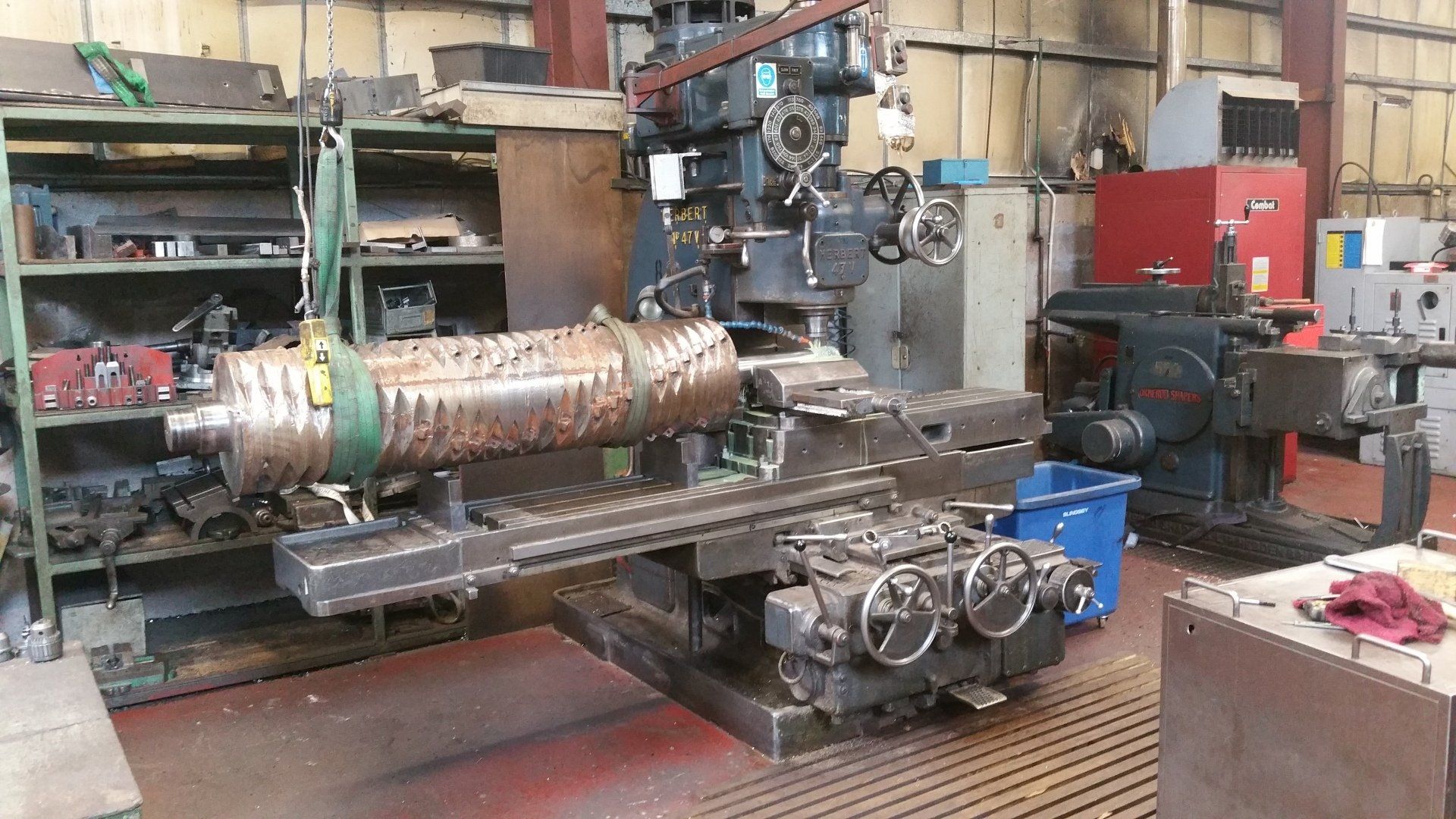

We have a fully equipped machine shop with a team of experienced engineers focused on component manufacture. We provide a quick manufacturing time whilst always maintaining a very high standard of manufacturing and keeping the pricing competitive.

We have an assembly unit with overhead crane with a maximum capacity of 2 Tonne. Here we construct the large assemblies that have been designed and manufactured by IJF engineering.